Maximizing productivity in a factory isn't as simple as it seems. Let's review some strategic factors that should be considered when looking into improving productivity.

For starters, the hours reported by workers are very different from what they sign-up for, and there's an obvious lack of tracking in this regard.

A study by the U.S. Department of Labor found that the average number of hours worked per week in manufacturing is around 40-50 hours, but some workers report working up to 60 hours per week.

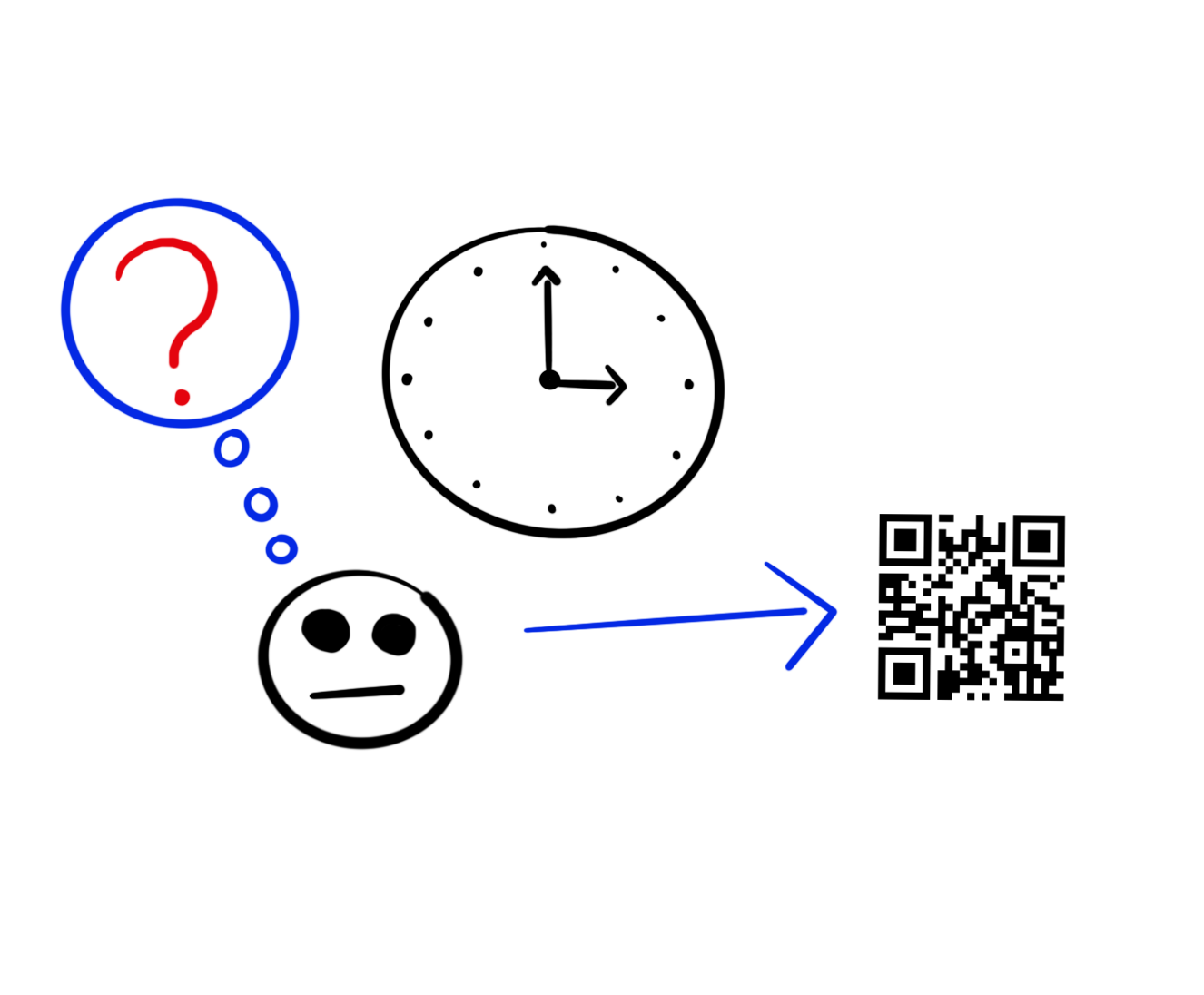

Aquiestoy is one of the solutions available to help you track your workers time at work, and avoid bloating your company with paper timesheet or spreadsheets.

Training your workers is an important matter. It's often overlooked but has disastrous productivity consequences.

According to a 2019 study by the National Center for the Middle Market, nearly half of middle market manufacturers (46%) believe that their employees lack the skills needed to operate advanced technologies.

The training you provide is a worthy investment. It comes to a cost but will reverse a lowering productivity curve as well as avoid incidents.

On top of being useful for you, it'll help motivate your workers that will find new ways to enjoy their daily work with those new acquired skills.

The lack of maintenance of the machines is also a factor decreasing productivity of factories and could be easily avoided by applying proper maintenance cycles.

According to a study by the International Society of Automation, the average downtime in manufacturing plants is around 5-10%.

It may seem obvious to some, but setting clear goals and streamlining the processes within a factory are also essential factors to increase efficiency drastically. Look at all your processes as a whole, dig-in and check what can be changed. Look at your worker and help them set up tangible goals to achieve on the short, mid and long-term.

Here are the five strategies summed-up:

| Strategy | Description |

|---|---|

| Streamline processes | Simplify production steps, optimize workflows, and automate what's possible. Technology like robotics and AI can reduce human error and boost efficiency. |

| Set clear goals and targets | Establish achievable goals for employees and the factory. Regular feedback loops and goal setting inspire purpose and encourage teamwork. This is often underestimated but the human factor is essential; you're building a relationship with your workers. |

| Adopt tracking for employee time management | Use tracking services like Aquiestoy for insightful data on employee breaks and work times. This data helps identify anomalies and generate useful insights. If applied correctly, it'll boost trust. |

| Provide training and development | Invest in employee training to enhance skills and efficiency. Regular training keeps employees up-to-date with industry trends and technologies. This will motivate them and give a great return on investment. |

| Maintain equipment and machinery | Regular maintenance prevents breakdowns and keeps operations smooth. Implement a preventive maintenance schedule and have regular inspections. |

By adopting these strategies, factory managers can optimize operations, increase productivity, and achieve better results.

Employee location and time tracking apps designed for manual labor and factory settings come in various forms, from simple clock-in/clock-out systems to more sophisticated solutions that use RFID tags, GPS, or other technologies to monitor employees' movements.

New processes are hard to follow, and creating a habit doesn’t come easily. Entire books have been written about it; lots of strategies are available.

Traditional timesheets or paper reports are solutions from the past that can be easily automatized nowadays. Thanks to Aquiestoy you could simplify the process and make it more accurate in just a few steps.

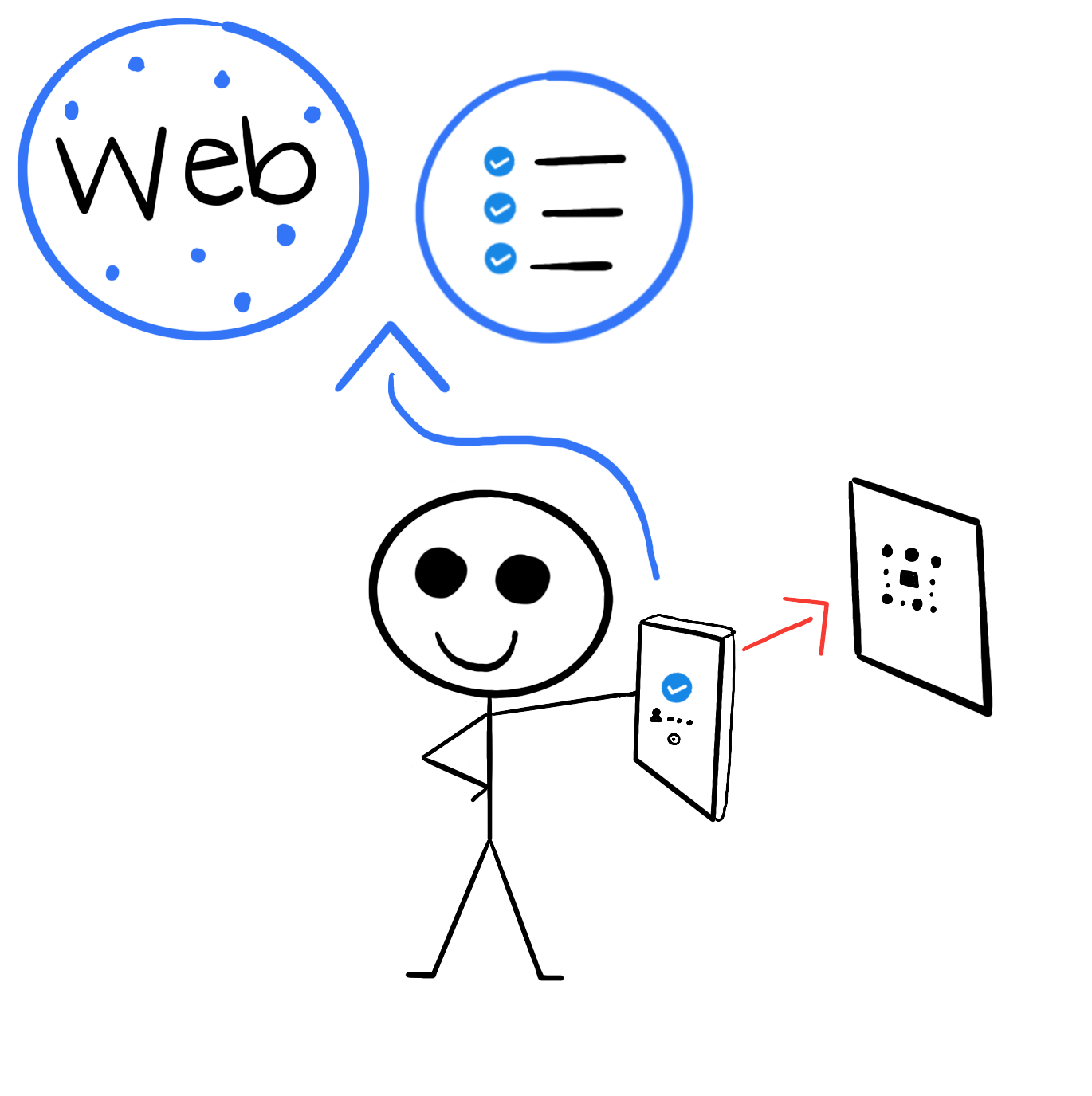

If you want to follow the time worked of your employees, one efficient solution is to have them use QR Codes to clock in and out of your company.

The idea behind QR Codes is simple, you can scan them with any imaging device, such as a camera and it’ll be interpreted through some kind of algorithm by your device.

We'll show you how you can build a tracker from scratch, and show you a free solution that could do it for you as an alternative.